- Telephone number: Log in to display

- FAX: Log in to display

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

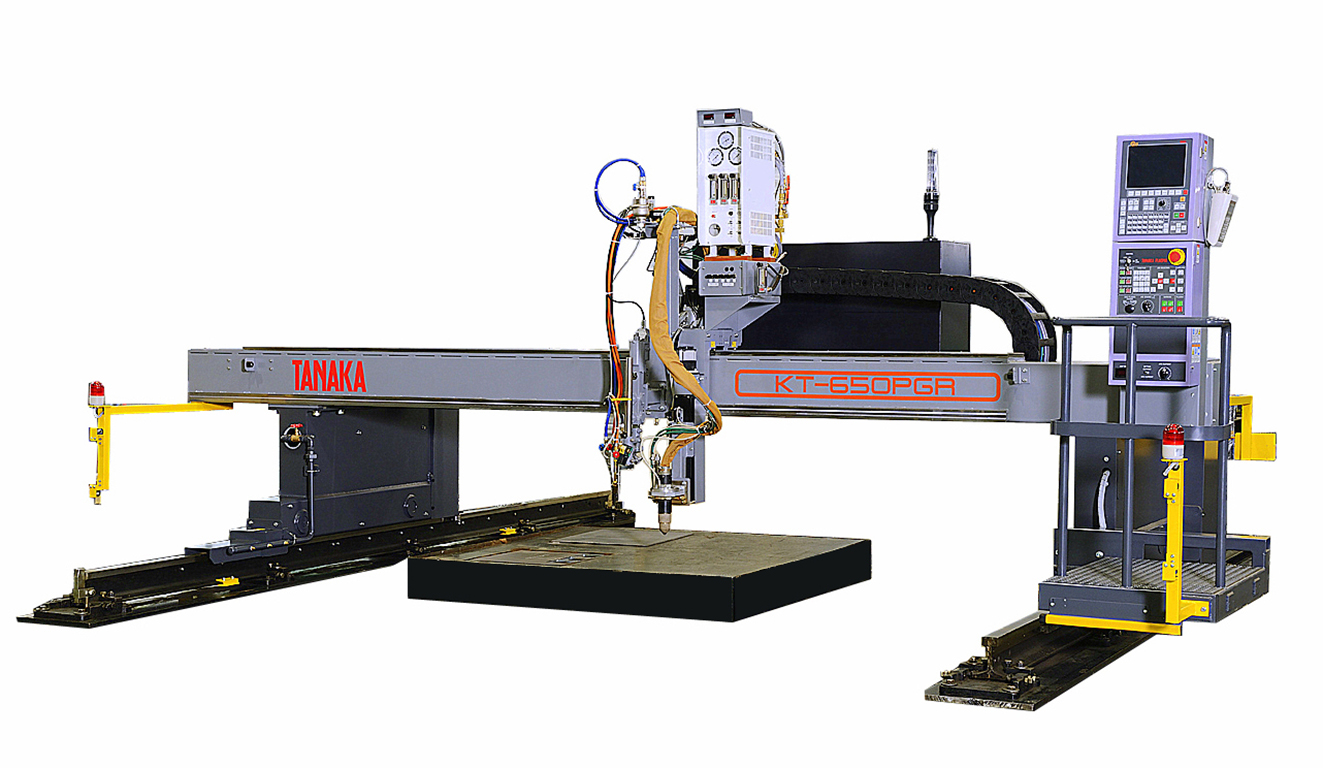

KT-650PGR Gas & Plasma Combined CNC Cutting Machine Thailand

Industry

Heavy electric machinery

Shipbuilding

Construction machinery parts

Specifications

- Materials:Iron

Steel

Stainless steel - Lots:1 lot (single item)

- Precision: ---

Conventional technologies/differences from other companies

High-speed" and "high-quality" cutting with plasma, and "multiple torch" and "thick plate" cutting with gas are all possible with this one machine!

High-speed cutting, which is a characteristic of plasma cutting, can be used to cut high-mix low-volume products in a short period of time. Gas cutting is used for thick plates that cannot be cut with plasma. In addition, a large number of products with the same shape can be efficiently cut by gas cutting with multiple torches. "KT-650PGR" will respond to various cutting applications.

【 feature 】

Equipped with NC device "Robo Q-15"

In-house manufactured NC unit specializing in gas cutting and plasma cutting applications, featuring easy operability. Supports USB input of NC data and wired/wireless LAN input.

*A FANUC NC unit can be installed upon request (optional)

Can be equipped with various plasma cutting devices

We will install the optimum plasma cutting equipment according to the steel type and cutting plate thickness.

・In-house Pegasus 500 series plasma cutting equipment

・Hypertherm HPR-XD series plasma cutting equipment

Stable high speed operation

The stable high-speed operation of the double-sided rack & pinion drive maximizes the advantages of plasma cutting.

[Airframe specifications]

Effective cutting width (mm) 3,000 to 5,000

Rail span (mm) 4,000 to 6,000

Effective cutting length Rail total length -2,500mm

Rail length 9,600 mm (standard) can be extended in 1,200 mm increments

Rail size 37kg/m or 50kg/m rail

NC controller Standard: RNQ-15

Optional: FANUC Series 32i

Plasma cutting device *¹ Standard: HPR260XD Oxygen plasma cutting device

Options: Other HPR-XD series, Pegasus series

Gas cutting device HC-326 blowpipe cutting (up to 4 units)

Cuttable materials: SS400, SM, SN, material, steel for bass, wash material, zinc material

Thickness that can be cut*¹

(SS400 mild steel) When gas cutting: t6 to t100mm

During plasma cutting: t6 to t32mm

Speed specification: Machining feed rate: 1 to 10,000mm/min

Rapid traverse speed: 24,000mm/min

Manual rapid traverse speed X-axis: 24,000mm/min

Y-axis: 24,000mm/min

*¹ The cutting specifications of the plasma cutting device differ depending on the plasma cutting device selected.

【 standard equipment 】

Arc height tracing function (plasma cutting)

Initial height sensing function (plasma cutting)

Plasma torch collision mitigation function (plasma cutting)

Coordinate rotation function (plasma cutting)

Cutting oxygen individual selection function (gas cutting)

Automatic lifting device selection function (gas cutting), etc.

[Optional specifications]

Stainless steel cutting function

Z marking device

Electrode consumption detection function

Separate type dust collector

air compressor

Positioning camera & monitor, etc.

*For detailed specifications, please contact our branch or sales office near you.

Company info

| Company name | NIPPON CUTTING & WELDING EQUIPMENT CO.,LTD | EMIDAS Member Number | 93885 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

U-Tai Phra Nakhon Si Ayutthaya Kingdom of Thailand |

| Telephone number | Log in to display | Fax number | Log in to display |

| Employees | 1,052,000,000 THB | Annual sales | |

| Employees | 86 | Person in charge | Matsukata |

| Type of manufacturing | Machine tools / Industrial machinery | ||

NIPPON CUTTING & WELDING EQUIPMENT CO.,LTD

NIPPON CUTTING & WELDING EQUIPMENT CO.,LTD