- Telephone number: Log in to display

- FAX: Log in to display

- Basic Info

- Equipment

- Technology & Products

- Map / HQ

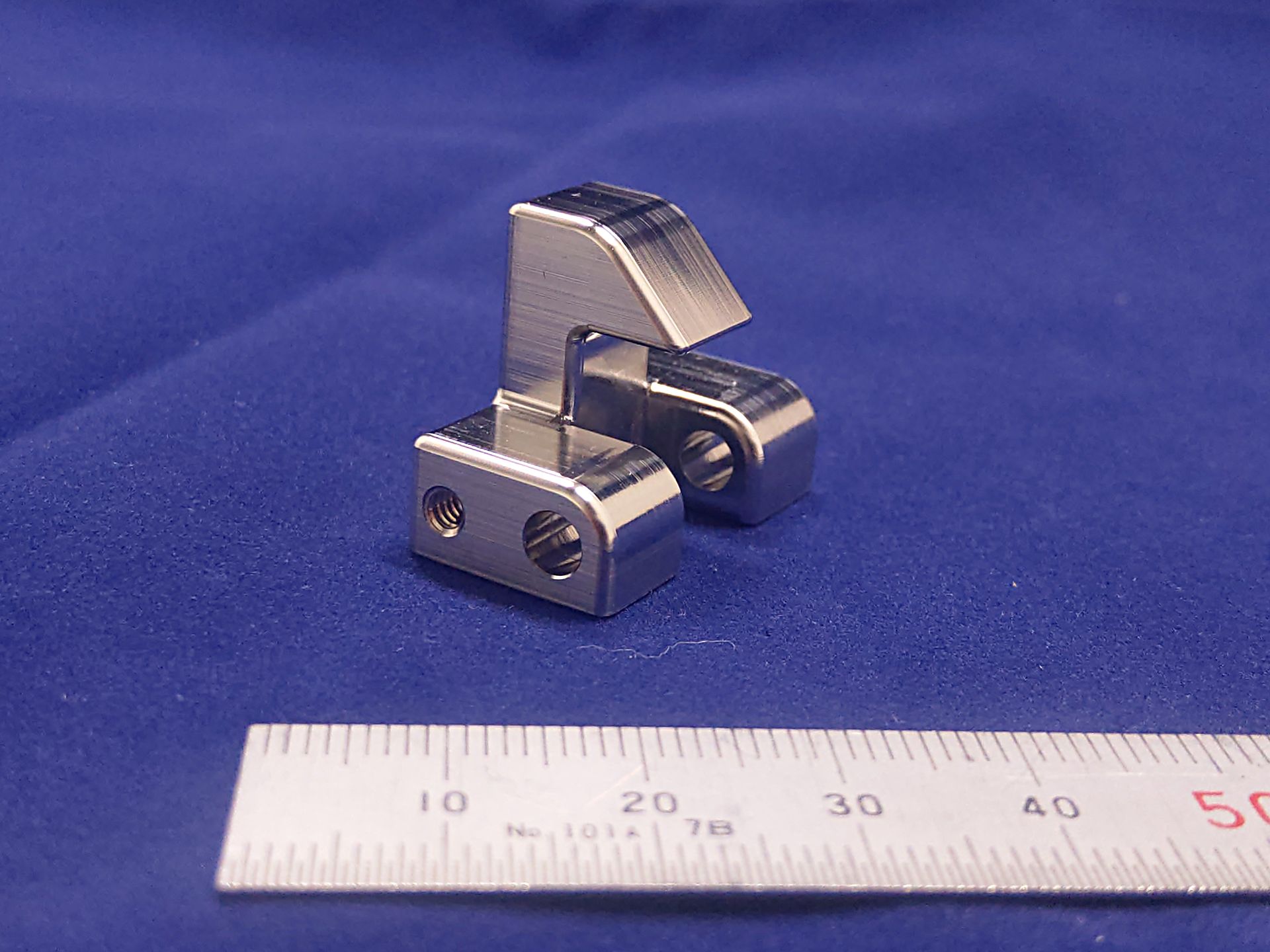

Whole circumference round processing of SUS304 material by 5-axis control

Industry

---

Specifications

- Materials: ---

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

"This is a SUS304 product processed by a 5-axis machining center.

The size is about 15mm x 20mm x 28mm, and the minimum groove width is 5mm. This is a ""whole circumference round"" product with R1mm on all corners except the bottom.

We use Matsuura MX-330 (10PC) as processing equipment. By carving out two products from one material and intentionally lengthening the processing time, we set it to operate efficiently even at night to enable quick delivery.

We use a ball end mill with R0.5 mm (2.5 mm under head, shank diameter 6 mm, protrusion amount 15 mm) for the radius part near the groove. It is processed by simultaneous 5-axis control while retracting tool and shank so that they will not interfere the product.

It is not impossible to process using 5-axis indexing, but thinking that it will not be finished cleanly due to the lengthening of the protruding amount of the tool and or need for a long neck tool, we choose to use 5-axis control machining using just barely interfere tools.

We have many achievements in whole circumference round processing using such 5-axis control.

Please feel free to contact us if you have any problems such as difficult processing with 3-axis machining.

<External dimensions>

15mm x 21mm x 28mm

Maximum size 500mm x 1,000mm x 380mm

<Materials we can handle>

A5052, A2024, A7075, S45C, S50C, NAK55, SUS303, SUS304, etc.

<CAD format we can accept>

Parasolid (x_t, x_b), STEP (STP), ACIS (SAT), DWG, DXF, IGES (IGS)"

Company info

| Company name | SIT Co., Ltd. | EMIDAS Member Number | 94902 |

|---|---|---|---|

| Country | Japan | Street address |

Nikaho City Akita Japan |

| Telephone number | Log in to display | Fax number | Log in to display |

| Employees | 30,000,000,000 JPY | Annual sales | |

| Employees | 13 | Person in charge | 齋藤 長之 |

| Type of manufacturing | Jigs and tools / Machine tools / Industrial machinery | ||

SIT Co., Ltd.

SIT Co., Ltd.