- Telephone number: +66-2-236-3102

- FAX: +66-2-236-4889

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

ROBO CARRY RACK , Thailand

Category

Industrial machinery

Brand name

NKC

Product info

Robo carry rack system

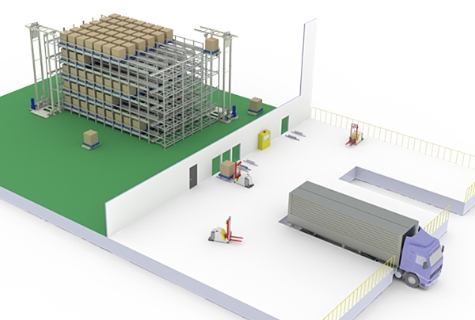

The unmanned logistics system enables total unmanned operation from the truck unloading area to the storage.

ROBO Carry Rack

The RoboCarry Rack System combines a high-density storage with a RoboCarry that can automatically put in and take out pallets to improve storage efficiency and unmanned operation.

Robo carry rack system

It is possible to deliver from receiving to storage to supply in one go with one Robo carry rack without remounting pallet products.

Enables unmanned operation and realizes forkliftless. By unmanning the factory, we can solve the serious labor shortage.

High storage efficiency

By reducing the number of conductors for loading and unloading from general pallet racks and automated warehouses, it has become possible to realize high-density storage warehouses.

Operational diversity

Robo Carry Rack supports various storage types. You can freely pre-pack, first-in, first-out, etc. in the storage.

The Robo Carry Rack is ideal for first-in and first-out of multi-lot products.

ROBO Carry

RoboCarry can perform various operations such as vertical / horizontal / corner driving and spine turn, and we can propose a layout that meets your needs.

Can handle up to 1 ton of heavy objects

It automatically charges while idling and does not require charging work.

There is no need to worry about man-made disasters because no human intervention is involved in the work. Since it has a built-in sensor, it is a safe and secure design that automatically stops when it detects a person or an obstacle.

Company info

| Company name | Thai Nakanishi Co., Ltd. | EMIDAS Member Number | 95833 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

Bangrak Bangkok Kingdom of Thailand |

| Telephone number | +66-2-236-3102 | Fax number | +66-2-236-4889 |

| Employees | 100,000,000 THB | Annual sales | |

| Employees | 23 | Person in charge | Kod (Mr.) |

| Type of manufacturing | Industrial machinery / Transportation equipment | ||

| Primary clients |

|

||