- Basic Info

- Equipment

- Technology & Products

- Map / HQ

Automatic gate cut (Chonburi, Thailand)

Industry

---

Specifications

- Materials: ---

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

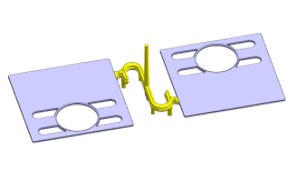

XUDONG HOLDINGS THAILAND CO., LTD. has developed a technology for automatic in-mold gate cutting using a 160-ton molding machine for PMMA (Polymethyl Methacrylate) clear resin molding, achieving full automation of the manufacturing process. This technology eliminates the need for post-gate processing, with a significant feature being the absence of EP (Epoxy Resin) marks. By molding two products at once, it significantly enhances production and cost efficiency.

Features

No Need for Post-Gate Processing: The in-mold gate cutting technology automatically detaches the gate from the molded product, eliminating the need for subsequent processing.

No EP Marks: Designed to leave no EP marks during the molding process, enhancing the aesthetic quality of the product.

Fully Automated Process: From product retrieval to gate cutting, the entire process is automated, reducing human error and maintaining consistent quality.

High-Efficiency Dual-Product Molding: Producing two products in a single molding cycle improves productivity.

Specifications

Resin Used: PMMA (Polymethyl Methacrylate), clear type.

Molding Machine: 160 tons.

Number of Products per Mold: Dual-product molding.

Features: No post-gate processing, no EP marks, fully automated process.

This technology is particularly beneficial for molding products made of PMMA resin, where transparency is required, as it reduces manufacturing costs and improves production efficiency. Additionally, it ensures high product quality, making it applicable in a wide range of fields, such as automotive parts, medical devices, and lighting fixtures.

Company info

| Company name | XUDONG MOLD (THAILAND) CO., LTD. | EMIDAS Member Number | 98767 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

T.Muang, A.Muang Chonburi Kingdom of Thailand |

| Telephone number | +66-38-111-560 | Fax number | +66-38-111-571 |

| Employees | 40,000,000 THB | Annual sales | |

| Employees | Person in charge | TAKASHI ASAKAWA |

XUDONG MOLD (THAILAND) CO., LTD.

XUDONG MOLD (THAILAND) CO., LTD.