1-10 / 3517 hits

Over the course of our company's long history, we have designed, manufactured and even provided on-site installation of numerous prototype machines to develop cutting-edge technology and large-scale production lines. Small items are fine too, so make sure you try our company's service. We firmly believe that our product will satisfy you.

| Main 3 products | Complete projects such as piping and canning Large can manufacturing (tanks, ducts, covers, piping) Glass-related manufacturing facilities |

|---|---|

| Type of manufacturing | Jigs and tools Industrial machinery |

| Recommended manufacturing category |

1:Designing - Industrial equipment designing - Industrial machinery designing 2:Assembly/Inspection - Repair - Industrial machinery repair 3:Assembly/Inspection - Assembly - Industrial machinery assembly 4:Product manufacturing - Production property - Other industrial machinery manufacturing 5:Product manufacturing - Plant equipment manufacturing - Plant equipment manufacturing 6:Product manufacturing - Construction and civil engineering machinery manufacturing - Pipe connection 7:Product manufacturing - Production property - Energy-saving equipment/Automatic instrument manufacturing 8:Product manufacturing - Production property - Carrier machine manufacturing 9:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 10:Development and production of prototype/Small-scale production - Sheet-metal processing - Chassis manufacturing |

| Main 3 products | ユニット・モジュール組立 設備設計・製作 |

|---|---|

| Type of manufacturing | Not selected Jigs and tools Office automation equipment |

| Recommended manufacturing category |

1:Assembly/Inspection - Assembly - Office equipment assembly 2:Parts manufacturing - Electric board and electronic part - Electronic parts assembly and wiring 3:Designing - Industrial equipment designing - Energy-saving machinery designing 4:Designing - Jig and tool designing - General jig designing 5:Designing - Jig and tool designing - Mass production jig designing 6:Assembly/Inspection - Assembly - Precision equipment assembly 7:Assembly/Inspection - Side job processing - Manual labor |

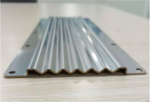

SUS303 Multiple Bending with Parallelism 0.3 We achieved a parallelism of 0.3mm through multiple bending processes using the hard material SUS303. Our Vietnam facility ensures stable supply of high-precision sheet metal products. Overview This is a case example of bending in precision sheet metal processing. Using SUS303, a material that is difficult to process, we carried out complex forming that included 13 wave-like bends and multiple bends at both ends. To meet stringent accuracy requirements, we optimized processing steps and material orientation, achieving high precision with parallelism of 0.3 mm. Features Material: SUS303 (a hard stainless steel prone to warping) Wave section: 13 bends; both ends: 3 bends each Processing size: 90 mm × 250 mm Flatness: within 0.3 mm Equipment used: AMADA HG1003 Press Brake Production volume: 200 units/month Capabilities Optimized grain direction of material to reduce the occurrence of warping. Changed bending sequence from “ends first” to “center first” to minimize processing distortion Conducted inspection using a 3D measuring machine to ensure stable dimensional accuracy Applications Financial equipment (deposit machines, ATMs) Office equipment Electronic equipment enclosures Achieving both multiple bends and high precision with hard material SUS303 is made possible by the experience and ingenuity of LEO ELECTRONICS. For more details, please download the PDF or feel free to contact us.

| Main 3 products | Pressed Parts Sheet Metal Parts Assembly |

|---|---|

| Type of manufacturing | Office automation equipment Electronic parts Medical equipment |

| Recommended manufacturing category |

1:Assembly/Inspection - Assembly - Precision equipment assembly 2:Product manufacturing - Medical equipment manufacturing - Medical equipment manufacturing 3:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining |

Mass Production of Safety-Critical Towing Hooks | Future Vietnam Production Capability Towing hooks are vital safety components that ensure vehicle security during towing operations. Our company has established mass production capabilities at our Japan facility and is preparing to expand production to our Vietnam plant in the future. - Overview Towing hooks are indispensable safety parts used during vehicle breakdowns and transport. It must exhibit high load-bearing capacity and impact resistance, and is therefore managed under the most stringent quality standards. At our Japan facility, we have established an integrated production system covering pressing, welding, and surface treatment. Looking ahead, we are preparing to introduce the same quality standards at our Vietnam site to build a stable local supply system. - Key Features • High strength ensured through arc welding • Enhanced corrosion resistance with cationic coating and zinc alloy plating • Automated production line covering bending, coating, and inspection • Future-ready production capability at the Vietnam base • As towing hooks are designated as critical safety components, they are manufactured under the strictest quality control to prevent failures that could lead to serious accidents - Processing Details • Material: High-strength steel • Processes: Pressing, bending, arc welding, projection welding • Surface treatment: Cationic coating, zinc plating • Inspection: Dimensional check, appearance inspection, strength testing Applications • Automotive towing hooks • Safety-related components Industries Served • Automobile manufacturers (e.g., Toyota, Daihatsu) • Automotive parts suppliers specializing in safety components Although towing hooks are not visible in daily use, they play a crucial role in ensuring safety during emergencies. We are preparing a production system at our Vietnam facility to meet growing demand with the same high standards of quality and reliability. ■ For more details, please download the PDF or contact us directly for consultation.

| Main 3 products | Cationic electrodeposition coating Pressing Press-fitting |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

1:Surface treatment - Coating - Electrodeposition coating 2:Assembly/Inspection - Assembly - Auto parts assembly 3:Auto parts manufacturing - Drive system part - Accelerator |

A snap that can be wrapped in your favorite color, a variety of sizes, and diverse fabrics.

| Main 3 products | Snaps Hooks |

|---|---|

| Type of manufacturing | Machine tools Home electrical appliances Electronic parts |

| Recommended manufacturing category |

1:Mass production - Metal press - Blanking 2:Assembly/Inspection - Assembly - Toy and sundries assembly 3:Mass production - Metal press - Brass 4:Mass production - Metal press - Thickness: 0.2 mm - 3.2mm 5:Die manufacturing - Press die - Designing 6:Die manufacturing - Press die - Part processing 7:Die manufacturing - Press die - Below 60 t |

| Main 3 products | Casting, Machining, Steel structure and machinery |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Assembly/Inspection - Inspection - Casting |

| Main 3 products | Tightening tools |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Electronic parts |

| Recommended manufacturing category |

1:Assembly/Inspection - Assembly - Precision equipment assembly |

Wire Harness

| Main 3 products | Wire harness for automotive Wire harness for motorcycle Wire harness for appliances |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

1:Assembly/Inspection - Assembly - Auto parts assembly |

TENPAKU Co., Ltd. Address : 88/109 Moo5 Tambon LamLukKa, Amphoe LamLukKa, Pathumtani 12150 TEL : +-66-2-987-0783 Reception time : 8.30-17.30 (Local time/2 hours behind Japan) Establish : September 2014 Capital stock : 4.9 million baht Number of employees : 11 people (including 2 Japanese engineers) Bank : KASIKORNBANK , Bangkok Bank

| Main 3 products | OVERHAUL |

|---|---|

| Type of manufacturing | Jigs and tools Industrial machinery Machine tools |

| Recommended manufacturing category |

1:Assembly/Inspection - Repair - Machine tool repair |

API's Radian PRO is the smallest, most accurate, versatile, and smartest laser tracker on the market. With a compact and sturdy design, the motors, encoders, and lasers are mounted on the aiming axis. Radian PRO has all the advantages of API's advanced laser tracking technology. - Provides optimal performance for trackers: - Higher accuracy - Robust construction and stable measurement - Thermal stability - Compact and flexible - Vertical, horizontal, and inverted measurement. Measurement Range: 100 m (328 ft) Horizontal Scan Speed 36 m/sec (20 ft/sec) - HeNe Laser (IFM) Class II (eye-safe) + Resolution 0.08 μm (0.0000031 in) + Accuracy Better Than ±0.5 ppm - Infrared Laser (ADM-Maxx) Class I (eye-safe) + Resolution 0.1 μm (0.0000039 in) + Locking Accuracy ±10 μm (±0.00039 in) or 1 ppm, whichever is greater - Operating Temperature -10º C to > 45º C (14º F to > 113º F) - Operating Range 0–25 m (0–82 ft) - Tracker Weight 9 kg (19.8 lb)

| Main 3 products | 3D Meter Portable 3-D coordinate measuring machin 3D profile scanner, cylindrical roundnes |

|---|---|

| Type of manufacturing | Jigs and tools Measuring machinery Industrial machinery |

| Recommended manufacturing category |

1:Assembly/Inspection - Inspection - Measuring |

1-10 / 3517 hits