- Telephone number: +81-53-465-0711

- FAX: +81-53-465-0714

- Website

- Basic Info

- Equipment

- Technology & Products

- Map / HQ

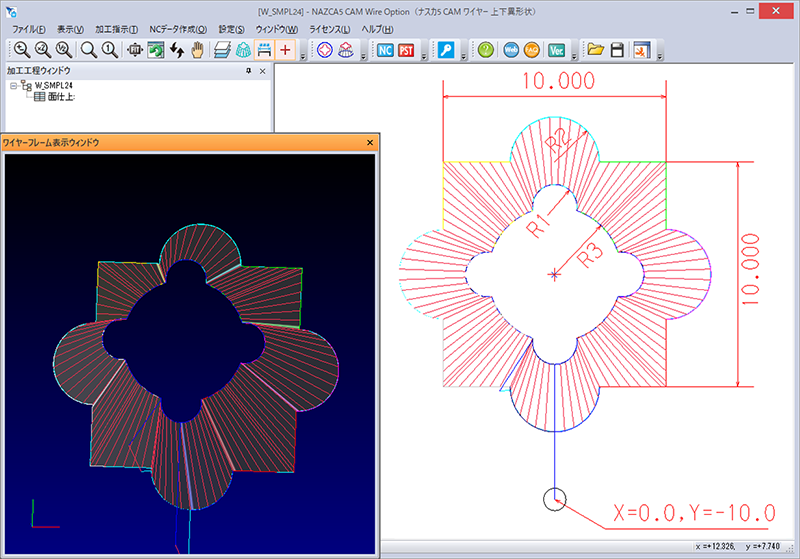

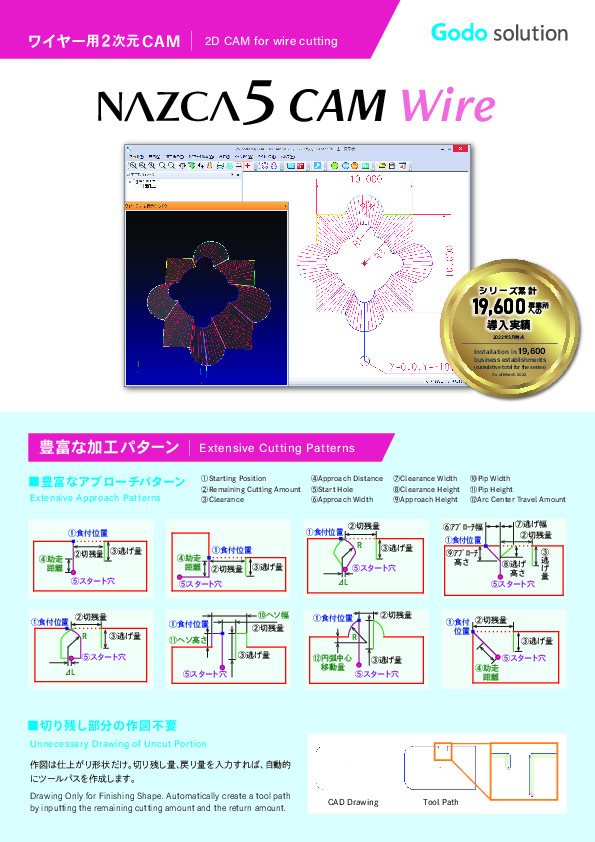

2D CAM for Wire (NAZCA5 CAM Wire)

Category

2D CAD/CAM

Brand name

NAZCA5 CAM Wire

Product info

It is also easy to give instructions for processing distinctive to wire cutting, in aspects such as type of processing and method of approach.

The platform can also handle various processing instructions for items including gear and taper shape, and top-bottom different shape.

■Extensive Machining Patterns

・Extensive Approach Patterns

・Automatically create a tool path by inputting the remaining cutting amount and the return amount.

■Editing the Tool Path

・Corner Deformation

Processing to insert the pin angle or deform the corner to prevent interference using just one click.

・Tapering

You can also give taper cut instructions by simply clicking on the path.

You can also change the angle for each element.

・Multi-cavity

The tool path can be easily copied, making it convenient when implementing multi-cavity.

You can copy grids, rotate copies, and more.

■Top-bottom different shape

・Creates complex shapes

・It is possible to insert the same corner R up and down

In the tapered cut, the lower corner expands, but in the vertical and horizontal functions, the same corner R can be inserted up and down.

■Accommodation of Windows 11

■Switchable language display (Japanese/English)

We are engaged in sales in Thailand based on a sales partnership agreement with NC Network Asia, a Thai corporation that is a member of the NC Network Group, which is developing business outside Japan.

Please contact us for detailed information.

Company info

| Company name | GODO SOLUTION Inc. | EMIDAS Member Number | 30003 |

|---|---|---|---|

| Country | Japan | Street address |

Hamamatsu-city, Shizuoka Japan |

| Telephone number | +81-53-465-0711 | Fax number | +81-53-465-0714 |

| Employees | 40,520,000 JPY | Annual sales | |

| Employees | 30 | Person in charge | sales staff |

| Primary clients |

|

||