- Telephone number: +81-565-52-3757

- FAX: +81-565-52-8567

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

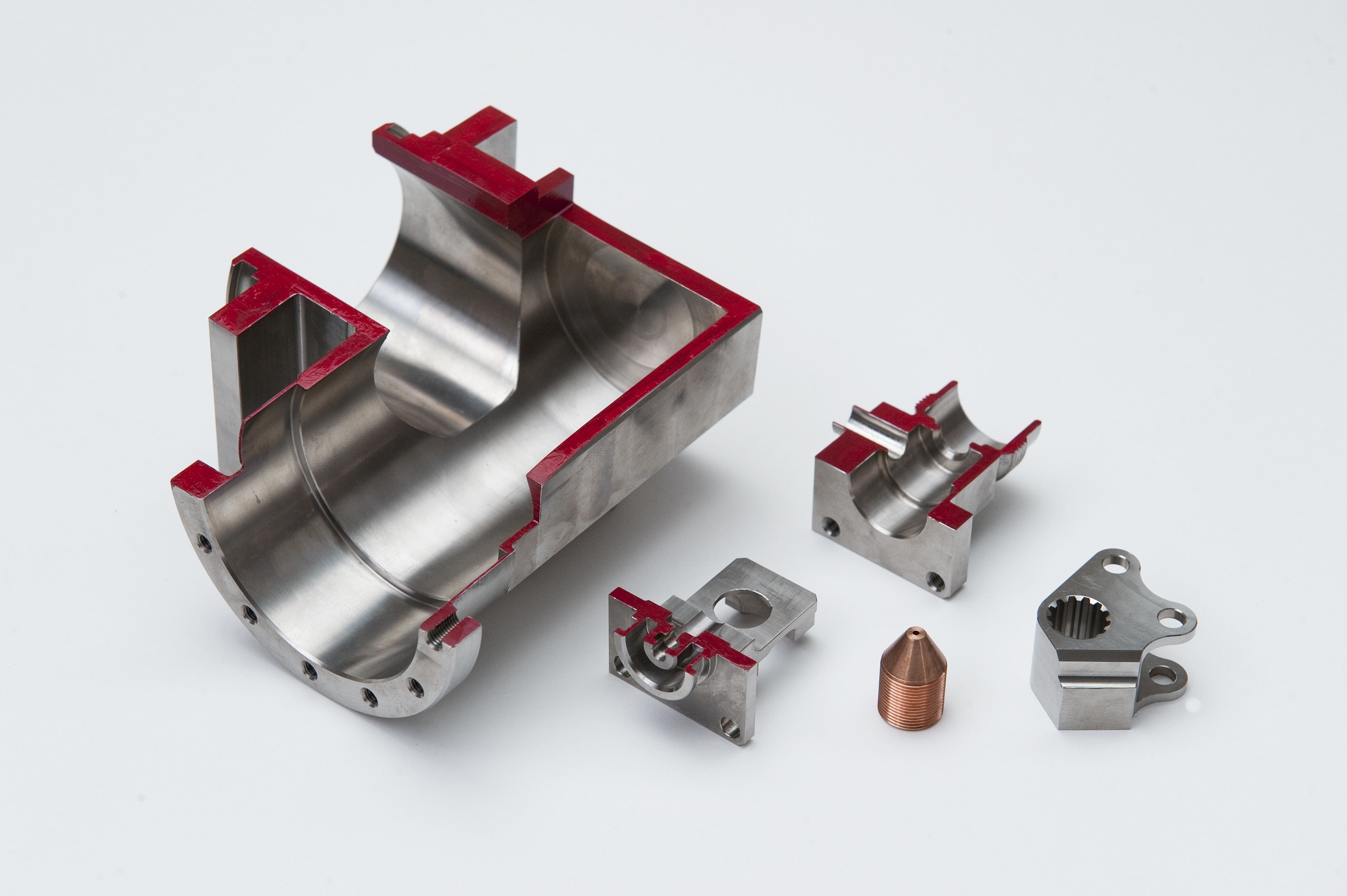

Aircraft Valve Components (Titanium Alloy, Inconel)

Industry

Aircraft

Robot

Manufacturing facilities

Specifications

- Materials:Titanium

Inconel - Lots:1 - 100 lots

- Precision:1/100 - 1/1,000 mm

Conventional technologies/differences from other companies

Aircraft Valve Components

‣Titanium Alloy

‣Inconel

‣Engine Parts (Internal Combustion)

‣5-Axis Machining

‣High Precision

‣Components for the Ministry of Defense, Internal Combustion Engines, Inconel, 5-Axis Machining, Precision Machining, Difficult-to-Machine Materials

‣5-Axis Machining, Coaxiality, Perpendicularity, Within 2 Microns, 3D Measurement

Aircraft Parts

We excel in precision machining of challenging materials like titanium, Inconel, alloy aluminum, and alloy stainless steel. Our expertise is especially strong in parts related to internal combustion engines and exhaust systems. We accommodate prototypes, small batch production, and very small quantity orders.

We can manage various components such as internal and external splines, special threads, gears, gear cutting, broaching, gear grinding, and thread grinding. We ensure precision using 3D measurement, image processing measurement, shape measurement, roundness measurement, and surface roughness measurement tools.

‣Lead Time: 2-5 weeks

‣Pricing: Contact us for a quote

‣Confidentiality: Your project's confidentiality is assured.

Company info

| Company name | Kito Seiki Seisakusho Co., Ltd | EMIDAS Member Number | 83448 |

|---|---|---|---|

| Country | Japan | Street address |

Toyota City Aichi Japan |

| Telephone number | +81-565-52-3757 | Fax number | +81-565-52-8567 |

| Employees | 20,000,000 JPY | Annual sales | |

| Employees | 50 | Person in charge | Hiroyuki+Watanabe |

| Type of manufacturing | Jigs and tools / Machine tools / Transportation equipment | ||