1-10 / 22758 hits

【Bar material】 【one chuck】 【lathe processing】 【automatic lathe】 The picture shows one-chuck processed product from bar material manufactured by automatic lathe. Size: φ6.0x12.0 Material: SUS316 Lot: 1000 or more Our automatic lathe workers have advanced technical skills, so please feel free to contact us for anything. Please contact us for precision cutting of metal from single item, prototype, development to mass production. ❐❐❐________________________________ Endo Co., Ltd. Sales Department: Nishijima Mobile: +818071657830 Email: shin-nishijima@endo-m.com Facebook: www.facebook.com/EndoFactory _________________________________❐❐❐ Website: https://www.en.endo-m.com/

| Main 3 products | Linear guide/actuator sliding parts Inkjet printer head parts Environmental analyzer related parts |

|---|---|

| Type of manufacturing | Industrial machinery Office automation equipment Medical equipment |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 2:Development and production of prototype/Small-scale production - Electrical discharge machine - Micro hole machining 3:Development and production of prototype/Small-scale production - Machining - Deep hole drilling 4:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Mass production - Grinding processing - NC plane grinding 7:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 8:Development and production of prototype/Small-scale production - NC machining - Machining (horizontal) 9:Mass production - Mechanical processing - Complex turning machining 10:Development and production of prototype/Small-scale production - Machining - Automatic lathe |

| Main 3 products | Piping parts for housing equipment Piping parts for machine tools Automotive pipe parts |

|---|---|

| Type of manufacturing | Machine tools Industrial machinery Transportation equipment |

| Recommended manufacturing category |

1:Mass production - Sheet-metal processing - Pipe bender processing 2:Development and production of prototype/Small-scale production - Sheet-metal processing - Pipe bending 3:Mass production - Sheet-metal processing - Pipe processing 4:Development and production of prototype/Small-scale production - Sheet-metal processing - Pipe machining 5:Mass production - Welding / welding - fixing with wax 6:Mass production - Metal press - Bulge forming die 7:Auto parts manufacturing - Drive system part - Steering device 8:Auto parts manufacturing - Engine - Fuel system 9:Auto parts manufacturing - Engine - Cooling system 10:Assembly/Inspection - Assembly - Auto parts assembly |

【Long-established integrated manufacturer of industrial packing and fluororesin gasket since 1907! Ono Corporation (Kobe, Hyogo & Sasebo, Kyushu)】 We are a long-established manufacturer of industrial packing and gaskets for the domestic market since 1907. We continue to strive every day by utilizing the "technology" and "know-how" we have developed during our over 100-year existence. Initially, our company produced gland packing. We currently manufacture a wide range of goods, including integrated production from PTFE (fluororesin) powder raw materials, engineering plastics, rubber, and metal processing. We create and support a wide range of products that are essential to people's lives. ~List of compatible products~ 〇Kobe factory〇 Fluororesin molding, resin processing, engineering plastic processing, gland packing, rubber molding, etc. related page⇒ https://en.nc-net.or.jp/company/74850/product/detail/109513/ 〇Kyushu factory〇 Metal processing, laser processing, sheet metal processing, can manufacturing processing, etc. related page⇒ https://en.nc-net.or.jp/company/74850/product/detail/109416/ 【Whats is OR-PACKING ?】 (Description in Japanese) https://www.nc-net.or.jp/company/74850/product/detail/205319/ 【What is OR Flon ?】 (Description in Japanese) https://www.nc-net.or.jp/company/74850/product/detail/180297 ◆Ono Corporation YouTube◆ Please see our YouTube channel for production process videos and manufacturing related trivia videos here! https://www.youtube.com/channel/UCPdFMm8DVM6g-8g14LkMSBg ※Please click "For more details" on the bottom to see our products and more information about us from our website♪ Ono Corporation Tokyo Sales Office TEL +813-3553-4651 FAX +813-3553-4654 Osaka Sales Office TEL +816-6582-9612 FAX +816-6582-9615 Kobe Sales Office TEL +8178-591-1201 FAX +8178-591-1227 Kyushu Sales Office TEL +81956-30-7331 FAX +81956-30-7320 URL https://www.ohnosha.co.jp/ e-mail info2@ohnosha.co.jp Instagram https://www.instagram.com/ohnosha_packing/ YouTube https://www.youtube.com/channel/UCPdFMm8DVM6g-8g14LkMSBg

| Main 3 products | Molding and Processing of PTFE and Teflon PEEK, Vespel, POM, MC Nylon Resin Processing Gland packing, metal gaskets, rubber O-rings, molded rubber products |

|---|---|

| Type of manufacturing | Heavy electric machinery Industrial machinery Transportation equipment |

| Recommended manufacturing category |

1:Mass production - Plastic - Fluororesin 2:Mass production - Rubber - Packing-related products 3:Mass production - Plastic - Engineering plastic 4:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 5:Mass production - Mechanical processing - Turning machining(plastic) 6:Development and production of prototype/Small-scale production - Machining - Milling (resin) 7:Development and production of prototype/Small-scale production - Machining - Machining (resin) 8:Mass production - Plastic - PEEK (polyetheretherketone) 9:Mass production - Rubber - Fluoro-rubber 10:Mass production - Rubber - NBR |

| Type of manufacturing | Not selected Jigs and tools Machine tools |

|---|---|

| Recommended manufacturing category |

1:Surface treatment - Lap polishing - Lap polishing 2:Development and production of prototype/Small-scale production - Jig manufacturing - Jig and tool manufacturing 3:Die manufacturing - Forging die - Cold forging die 4:Die manufacturing - Forging die - Hot forging die 5:Development and production of prototype/Small-scale production - NC machining - NC milling 6:Development and production of prototype/Small-scale production - Electrical discharge machine - Electric discharge machining 7:Development and production of prototype/Small-scale production - Grinding processing - Internal grinding |

| Type of manufacturing | Transportation equipment Industrial machinery Construction material |

|---|---|

| Recommended manufacturing category |

2:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 3:Development and production of prototype/Small-scale production - Blank cutting - Laser and turret punch press processing 4:Parts manufacturing - Spring - Thin leaf spring 5:Development and production of prototype/Small-scale production - Machining - Spinning 6:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 7:Development and production of prototype/Small-scale production - Blank cutting - Nitrogen cutting |

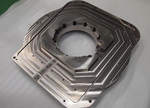

"This is a base plate for high-precision machine tools. The material is SUS303. We annealed the plate material of SUS303 and processed it by turning process and machining. This is a product that takes time to process due to its high precision and processing, but we were able to produce it well by our integrated production, which is our strength. The machining accuracy is 0.01 mm for parallelism, 0.01 mm for concentricity, and 0.02 for hole position accuracy. 【Processing equipment】 ・Vertical NC lathe Okuma V60-R ・Vertical machining center Makino V77L Please feel free to contact us for any product. Industry: for machine tools Product name: base plate Material: SUS303 (annealed) Size: 400 x 400 x 50 Accuracy: parallelism 0.01 mm, concentricity 0.01 mm, hole position accuracy 0.02 Lot: 2-4 pieces Processing days: 1 month <<< Abundant equipment that enables integrated production >>> We have abundant equipment such as large 5-sided processing machines with a maximum of 6,000 x 1,800, 5-axis processing machines, NC combined lathes, turning centers, flat surfaces, cylinders, various grinding machines, gun drill machines, etc. ※We will cooperate with subcontract factories for equipment we do not have such as wire cuts, to enable integrated production. Glory is a professional of ""large scale"", ""casting"", and ""complex shape processing"". We can handle a wide range of products from iron castings such as FC / FCD to aluminum castings such as AC. We specialize in large-scale processing up to 6000mm x 1800mm. Lot from 1 piece, and various processing is possible. Feel free to contact for a quotation to Komori (sales person). GLORY CO.,LTD. 8587, Minami Minowa-mura, Kamiina-gun, Nagano Prefecture, 399-4511 TEL: +81-265-73-9324 FAX: +81-265-73-2865 Person in charge: Ohara"

| Main 3 products | Ultra-precision metal processing Large casting parts processing Aluminum product processing (including AC) |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 3:Development and production of prototype/Small-scale production - NC machining - NC milling 4:Development and production of prototype/Small-scale production - NC machining - NC vertical lathe 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Grinding processing - NC plane grinding 7:Development and production of prototype/Small-scale production - Grinding processing - NC cylindrical grinding 8:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 9:Development and production of prototype/Small-scale production - NC machining - Combined lathe machining 10:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing |

"Proposal of camera cleaning unit for automobiles Small DC pump (micropump mechanism / structural design) / housing molding / assembly ① ADAS driving support & security Back monitor parts for driving support system ② Small DC pumps (micro pumps) are proposed from the mechanical and structural design and produced at our factory. ③ Some of the resin molded products, (including housing molding) are produced at our factory. Features High flow rate, high pressure, optimal unit design (1) Achieve cleaning power with high flow rate and high pressure. (2) Further noise reducing and vibration by designing the mechanism and structure of the unit. Application Automobile parts, cleaning pump unit for back monitor For cleaning camera lenses Improve monitor visibility * We will respond promptly to inquiries □□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□ TADA PLASTIC INDUSTRIAL CO.,LTD. 2-12-8, Tsudo, Fujiidera Shi, Osaka, Japan 583-0037 TEL:0081-729540981 http://www.tadapla.co.jp Ideas and technology that lead to innovation Fusion technology Injection molding Urethane foam Micro pump Precision rubber molding □□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□

| Main 3 products | Compact DC pump Injection molding Urethane foam |

|---|---|

| Type of manufacturing | Transportation equipment Electronic parts Medical equipment |

| Recommended manufacturing category |

1:Mass production - Plastic - PU (polyurethane) 2:Mass production - Plastic - Expansion molding 3:Mass production - Plastic - GFRP (glass fiber reinforced plastic) 4:Mass production - Plastic - Gas injection 5:Mass production - Plastic - Injection molding 6:Mass production - Plastic - 60 - 300 t 7:Mass production - Plastic - PPS (polyphenylene sulfide) 8:Mass production - Plastic - CFRP (carbon fiber reinforced plastic) 9:Mass production - Plastic - PBT (polybutylene terephthalate) 10:Mass production - Plastic - Elastomer |

At our job heat treatment plant, we provide a wide variety of processes. The photo shows a machine tool axle being hardened by our large vertical scan hardening machine. The gap between the workpiece and copper colored coil is extremely close. If the coil gap is too large, the following quality defects can occur. ・For shafts, if the coil is off center, the hardened casing becomes uneven. ・Longer time required for heating increases the risk of overheating. ・The area surrounding the target area is also induction heated, resulting in power loss. To prevent these defects, we design coils with the optimal coil gap. To prevent contact between the coil and workpiece, which can cause a short circuit and damage the workpiece, the coils are moved to the required distance from the workpiece before heating. While time consuming, these check measures ensure the highest quality hardening process in the industry. ~Induction Hardening Job Heat Treatment Coil Gap~

| Main 3 products | Induction job heat treatment Manufacturing and sales of induction heating machinery and parts Manufacturing and sales of transistorized converters and parts |

|---|---|

| Type of manufacturing | Machine tools Industrial machinery Transportation equipment |

| Recommended manufacturing category |

1:Surface treatment - Heat treatment - High frequency quenching 2:Surface treatment - Heat treatment - Quenching 3:Surface treatment - Heat treatment - Annealing 4:Product manufacturing - Production property - Other industrial machinery manufacturing 5:Surface treatment - Heat treatment - Full annealing 6:Surface treatment - Heat treatment - Straightening annealing 7:Surface treatment - Heat treatment - Stress relief annealing (SR treatment) 8:Surface treatment - Heat treatment - Austempering 9:Surface treatment - Heat treatment - Sub-zero treatment 10:Surface treatment - Heat treatment - Air quenching |

Our workflow, from order to delivery, can provide fast delivery as well as quick estimates, low costs and high quality.

| Main 3 products | Industrial machine parts Mold components Semiconductor equipment parts |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 2:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 3:Die manufacturing - Plastic mold - Part processing 4:Development and production of prototype/Small-scale production - NC machining - NC milling 5:Die manufacturing - Press die - Plate machining 6:Surface treatment - Plating/Chemical conversion treatment - Iron 7:Surface treatment - Plating/Chemical conversion treatment - Aluminum |

| Type of manufacturing | Industrial machinery Telecommunication equipment Medical equipment |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Sheet-metal processing - Chassis manufacturing 2:Mass production - Welding / welding - Robot welding 3:Mass production - Welding / welding - Fiber welding 4:Mass production - Blank cutting - Laser and turret punch punching 5:Mass production - Sheet-metal processing - Bending process 6:Mass production - Sheet-metal processing - Precision sheet metal processing 7:Mass production - Blank cutting - CO2 laser processing 8:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 9:Development and production of prototype/Small-scale production - Machining - Stainless steel 10:Development and production of prototype/Small-scale production - Machining - Iron |

1-10 / 22758 hits