1-10 / 8036 hits

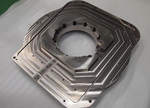

・ Material: Aluminum ・ Dimensions: 350 × 350 × 300 mm ・ Key Features: ・ Precision machining with our 5-axis/multi-axis machines for high efficiency and accuracy. ・ The demand for complex shapes like this is rising due to electrification needs, and these designs are achievable only through CAD/CAM and 5-axis/multi-axis machining. ・ We also support full machining with ADC and AC4C materials. Supported Materials ・Metals: Aluminum, Stainless Steel, Inconel, Titanium, Hastelloy, Super Invar (Invar), Pure Nickel, Tungsten Alloy, Iron, Copper, etc. ・Plastics: High-performance resins (PA66-GF30, PPS-GF40, PBT-GF30, PEEK-GF30, etc.), General-purpose resins (ABS, PP, PA, PMMA, etc.) Available Equipment ・5-Axis Machines ◎ Makino Milling Machine DA300 (5-axis with pallet changer) ◎ DMGI DMC 60 U duoBLOCK ◎ Mori Seiki NMV5000 DCG ◎ Matsuura Machinery MAM72-63V (with pallet changer) ◎ Matsuura Machinery MX-330 (with pallet changer) ◎ GF Machining Solutions MIKRON HSM 600U (with pallet changer) ◎ GF Machining Solutions MIKRON HSM 400U (with pallet changer) ・Multi-Axis Machines ◎ Mori Seiki NT4250 DCG ◎ Okuma MALTUS B300II ◎ AMADA A-18S Kodama Corporation Co., Ltd. 205-0002 3-3-9 Sakae-cho, Hamura-shi, Tokyo TEL: (042) 570-6891 FAX: (042) 570-6892 Website: https://www.kodamacorp.co.jp Email: oume@kodamacorp.co.jp

| Main 3 products | Metal Prototyping Model (Aluminum) Stainless Steel Inconel |

|---|---|

| Type of manufacturing | Industrial machinery Transportation equipment Medical equipment |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Simultaneous 5-axis machining 2:Development and production of prototype/Small-scale production - NC machining - Combined lathe machining 3:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 4:Development and production of prototype/Small-scale production - Prototype processing - Simplified/Molding 5:Development and production of prototype/Small-scale production - NC machining - Handles 3D processing 6:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 7:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 8:Development and production of prototype/Small-scale production - Machining - Stainless steel 9:Development and production of prototype/Small-scale production - Machining - Titanium alloy 10:Development and production of prototype/Small-scale production - Machining - Machining (resin) |

It is a prototype of medical equipment parts. In our company, mass production to suit your needs Please leave medical equipment parts to us with quick delivery SUS Material Handling, such as : SUS303 SUS304 SUS316 SUS420J SUS430 SUS630

| Main 3 products | Long length machining processing Highly precise jig boring Parallel machining process |

|---|---|

| Type of manufacturing | Machine tools Industrial machinery Medical equipment |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 2:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 3:Development and production of prototype/Small-scale production - Grinding processing - Plane grinding 4:Development and production of prototype/Small-scale production - Machining - Planer machining 5:Development and production of prototype/Small-scale production - Machining - Deep hole drilling 6:Development and production of prototype/Small-scale production - Machining - Straightening 7:Development and production of prototype/Small-scale production - NC machining - NC milling 8:Development and production of prototype/Small-scale production - Machining - Stainless steel 9:Development and production of prototype/Small-scale production - Machining - Iron 10:Development and production of prototype/Small-scale production - Machining - Aluminum alloy |

| Main 3 products | precision titanium machining ultra-precision machining micro-hole machining |

|---|---|

| Type of manufacturing | Machine tools |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Automatic lathe 2:Development and production of prototype/Small-scale production - NC machining - Combined lathe machining 3:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 4:Development and production of prototype/Small-scale production - Machining - Titanium alloy 5:Development and production of prototype/Small-scale production - Machining - Stainless steel 6:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 7:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 8:Development and production of prototype/Small-scale production - NC machining - Machining (horizontal) 9:Development and production of prototype/Small-scale production - Grinding processing - NC plane grinding 10:Development and production of prototype/Small-scale production - Grinding processing - Form grinding |

"This is a base plate for high-precision machine tools. The material is SUS303. We annealed the plate material of SUS303 and processed it by turning process and machining. This is a product that takes time to process due to its high precision and processing, but we were able to produce it well by our integrated production, which is our strength. The machining accuracy is 0.01 mm for parallelism, 0.01 mm for concentricity, and 0.02 for hole position accuracy. 【Processing equipment】 ・Vertical NC lathe Okuma V60-R ・Vertical machining center Makino V77L Please feel free to contact us for any product. Industry: for machine tools Product name: base plate Material: SUS303 (annealed) Size: 400 x 400 x 50 Accuracy: parallelism 0.01 mm, concentricity 0.01 mm, hole position accuracy 0.02 Lot: 2-4 pieces Processing days: 1 month <<< Abundant equipment that enables integrated production >>> We have abundant equipment such as large 5-sided processing machines with a maximum of 6,000 x 1,800, 5-axis processing machines, NC combined lathes, turning centers, flat surfaces, cylinders, various grinding machines, gun drill machines, etc. ※We will cooperate with subcontract factories for equipment we do not have such as wire cuts, to enable integrated production. Glory is a professional of ""large scale"", ""casting"", and ""complex shape processing"". We can handle a wide range of products from iron castings such as FC / FCD to aluminum castings such as AC. We specialize in large-scale processing up to 6000mm x 1800mm. Lot from 1 piece, and various processing is possible. Feel free to contact for a quotation to Komori (sales person). GLORY CO.,LTD. 8587, Minami Minowa-mura, Kamiina-gun, Nagano Prefecture, 399-4511 TEL: +81-265-73-9324 FAX: +81-265-73-2865 Person in charge: Ohara"

| Main 3 products | Ultra-precision metal processing Large casting parts processing Aluminum product processing (including AC) |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 3:Development and production of prototype/Small-scale production - NC machining - NC milling 4:Development and production of prototype/Small-scale production - NC machining - NC vertical lathe 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Grinding processing - NC plane grinding 7:Development and production of prototype/Small-scale production - Grinding processing - NC cylindrical grinding 8:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 9:Development and production of prototype/Small-scale production - NC machining - Combined lathe machining 10:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing |

[Water jet cutting process, iron, aluminum, stainless steel, zero heat generation] We perform cutting processing with a water jet. It is possible to cut various materials such as iron, aluminum, and stainless steel. Since water is used for processing, it can be processed without being affected by heat. Cutting is performed with ultra-high pressure water. Since no tools are used for machining, heat is not generated during machining and there is no deterioration or discoloration of the work. Therefore, it is ideal for processing heat-sensitive materials and suppressing distortion. We are also good at various laser processing. For cutting large sheet metal parts, leave it to Insmetal. http://www.insmetal.co.jp/lc.html

| Main 3 products | Folded product General welded products Laser/Welding |

|---|---|

| Type of manufacturing | Heavy electric machinery Industrial machinery Construction material |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Blank cutting - Laser processing (longer than 121.2 m) 2:Development and production of prototype/Small-scale production - Prototype processing - Welding 3:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 4:Development and production of prototype/Small-scale production - Sheet-metal processing - Pipe machining 5:Development and production of prototype/Small-scale production - NC machining - Handles 3D processing 6:Development and production of prototype/Small-scale production - Sheet-metal processing - Sheet metal protocol manufacturing 7:Development and production of prototype/Small-scale production - Sheet-metal processing - 3D pipe machining 8:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing 9:Development and production of prototype/Small-scale production - Blank cutting - Nitrogen cutting 10:Development and production of prototype/Small-scale production - Prototype processing - Chassis prototype manufacturing |

"This is a part for medical and rehabilitation equipment with a size of 30 mm x 50 mm x 80 mm. The material is A5052. We used FANUC ROBODRILL α-T21iD and Seibu M50B wire cut machine. We have vertical machining centers, 5-axis machining centers, NC lathes, wire cuts, and surface grinders, and have a track record of processing a wide range of genres such as infrastructure-related, medical-related, and hobby-related items. We also handle welding and surface treatment. In addition to aluminum, we handle a wide variety of materials such as stainless steel, iron, and brass. Please feel free to contact us. <External dimensions> Maximum size 500mm x 1,000mm x 380mm <Materials we can handle> A5052, A2024, A7075, S45C, S50C, NAK55, SUS303, SUS304, etc. <CAD format we can accept> Parasolid (x_t, x_b), STEP (STP), ACIS (SAT), DWG, DXF, IGES (IGS)"

| Main 3 products | Jig for mass production Precision machine parts Automatic machine, labor saving machine, manufacturing and assembly |

|---|---|

| Type of manufacturing | Not selected Jigs and tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 2:Development and production of prototype/Small-scale production - Machining - Simultaneous 5-axis machining 3:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 4:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Electrical discharge machine - Wire electric discharge machining 7:Development and production of prototype/Small-scale production - Grinding processing - Plane grinding 8:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 9:Development and production of prototype/Small-scale production - Machining - Iron 10:Development and production of prototype/Small-scale production - Machining - Stainless steel |

[We provide quick service! Machining/cutting] S50C 26.5X89X6 Chuck arm for machine equipment ▼Material Iron S50C ▼Size 26.5X89X6 ▼Processing method Machining ▼Accuracy Pitch/hole diameter: ±0.02 ▼Lot About 1 to 10 pieces/month *We specialize in single items and small quantities. ▼Processing days About 10 days *Please contact us as it varies depending on the shape and production status. ▼Industry Machine equipment ▼Product name Chuck arm ▼Features The photo shows example of machining process. These are parts for machine equipment. We ask partner companies for material procurement to surface treatment such as plating to provide integrated production. Processing period for this item is around 10 days. ▼Others We handle urgent orders. We mainly handle single items. Please contact us regarding materials such as resin, steel, and stainless steel. ==================== DEGAWA CORPORATION https://www.degawa.jp Fujisawa Plant 5-3-7 Fujisawa, Fujisawa City, Kanagawa Prefecture 251-0052 Nihonmatsu Factory 82-8 Miyato, Nihonmatsu City, Fukushima Prefecture 964-0811 ★Contact Nihonmatsu factory for inquiries★ TEL: +81-243-22-2474 FAX: +81-243-22-1543 Person in charge: Takamichi Saito ====================

| Main 3 products | Manufacture of "Pipe Slider" |

|---|---|

| Type of manufacturing | Jigs and tools Industrial machinery Transportation equipment |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 2:Development and production of prototype/Small-scale production - Jig manufacturing - Jig and tool manufacturing 3:Development and production of prototype/Small-scale production - Jig manufacturing - Mass production jig manufacturing 4:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Machining - Lathe machining (resin) 7:Development and production of prototype/Small-scale production - Electrical discharge machine - Wire electric discharge machining 8:Development and production of prototype/Small-scale production - Machining - Copper alloy 9:Development and production of prototype/Small-scale production - Machining - Stainless steel 10:Development and production of prototype/Small-scale production - Machining - Aluminum alloy |

[Aircraft parts] Specially shaped products form Inconel 【Product name】 BOSS 【Material】 Inconel / AMS5706 (ams5706) 【Size】 Φ19.9×37 【Lot】 1 to 200 pieces/month 【Precision】 Within general tolerance 【Processing method】 Lathe, machining, wire cut 【Industry/usage】 Airplane 【Features】 It has a slightly unique shape, slanted like the Leaning Tower of Pisa, yet it is machined and wire-cut using in-house jigs. We achieved the accuracy by processing without removing it from the jig. Unfortunately, it is not visible in the photo, but the bottom section (the part that contacts the red fabric) is not cut in a straight line, but rather in a semicircular shape. We specialize in machining items with slightly special shapes using difficult-to-cut materials. Please contact us for special shaped products made of difficult-to-cut materials or difficult-to-cut products. ≪Contact us≫ Ito Seiko Co., Ltd 13-12 Tobi Mochida, Nikaho-shi, Akita TEL:+81184-38-3846 FAX:+81184-38-3826 Person in charge:Jun Ito, Kei Ito

| Main 3 products | Precision mechanical parts Aircraft related parts Automotive related parts |

|---|---|

| Type of manufacturing | Industrial machinery Electronic parts Transportation equipment |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - Electrical discharge machine - Wire electric discharge machining 3:Development and production of prototype/Small-scale production - Grinding processing - NC plane grinding 4:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 5:Development and production of prototype/Small-scale production - Jig manufacturing - General jig manufacturing 6:Development and production of prototype/Small-scale production - Jig manufacturing - Mass production jig manufacturing 7:Development and production of prototype/Small-scale production - Machining - Stainless steel 8:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 9:Development and production of prototype/Small-scale production - NC machining - Handles 2.5-dimensional processing 10:Mass production - Mechanical processing - High precision |

Aluminum microfabrication technology: We have achieved horizontal microfabrication on A5052 with a diameter of 100 microns (0.1 mm), a depth of 300 microns (0.3 mm) and a pitch distance of 300 microns (0.3 mm). We also develop ultra-fine burr treatment.

| Main 3 products | Aluminum precision parts for semiconductor and LCD manufacturing equipment Aluminum precision parts for medical devices Microfabricated parts (can handle all types of materials) |

|---|---|

| Type of manufacturing | Industrial machinery Medical equipment Jigs and tools |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 2:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 3:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 4:Development and production of prototype/Small-scale production - Machining - Handles microfabrication 5:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing 6:Development and production of prototype/Small-scale production - Prototype processing - Chassis prototype manufacturing 7:Development and production of prototype/Small-scale production - NC machining - Combined lathe machining 8:Development and production of prototype/Small-scale production - NC machining - Handles 3D processing 9:Surface treatment - Polishing/Lapping - Mirror polishing 10:Surface treatment - Plating/Chemical conversion treatment - Aluminum |

Jig, gauge head, nozzles, tools, attachment, electronic parts, etc. We handle single item of metal processing in short delivery time by making full use of NC lathe, NC milling, MC, general-purpose machining, wire cutting, small hole electric discharge machining, internal surface grinding, cylindrical grinding, parallel grinding, 3D CAD / CAM program processing. Materials we can handle are S10C to S45C, SCM, SKD, various pre-hardened steel, SUS304, SUS303, SUS316, SUS310, SUS410, SUS420j2, SUS440C, A5052, 2017, 7075, 6000 series, titanium, inconel, etc. We also handle: vacuum hardening, salt hardening, induction hardening, carburizing, gas soft nitriding, fire hardening, etc. Hard chrome plating, electroless nickel plating, black chrome plating, unichrome plating, etc. Alumite treatment, aluminum coloring treatment, raydent treatment, trivalent chromate, hexavalent chromium passivation, etc. Lathe processing, milling processing, NC MC, grinding processing, 3D CAD/CAM, etc.

| Main 3 products | Tools (shanks, bits, etc.) Precision prototype processing (various jigs, flanges, etc.) High precision spindle gauge (taper / straight / arbor) |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Measuring machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 2:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 3:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 4:Development and production of prototype/Small-scale production - Machining - General-purpose lathe machining 5:Development and production of prototype/Small-scale production - Grinding processing - Cylindrical grinding 6:Development and production of prototype/Small-scale production - NC machining - Handles 3D processing 7:Development and production of prototype/Small-scale production - Electrical discharge machine - Wire electric discharge machining 8:Development and production of prototype/Small-scale production - Electrical discharge machine - Electric discharge machining 9:Product manufacturing - Production property - Machine tool manufacturing 10:Product manufacturing - Production property - Blade manufacturing |

1-10 / 8036 hits